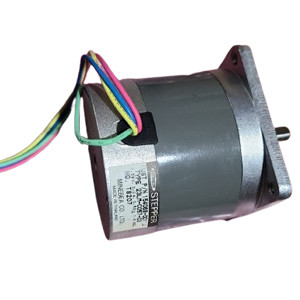

Stegia Stepper Motor A008632 | Brand New |

(0 reviews)

Sold by:

Inhouse product

Inhouse product

Price:

৳3,500.00

/1

Share:

Top Selling Products

-

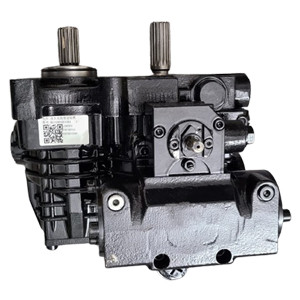

REXROTH Hydraulic Valve R901226876 | New |

৳10,500.00

Stegia Stepper Motor A008632 | Original |

Motor

Part No: A008632

Brand: Stegia

Condition: New

Availability: In Stock

Ships: Fast and Reliable Shipping

Brand New

There have been no reviews for this product yet.

Related products

৳13,500.00

Minebea 23LM-C057-03 Bipolar Stepper Motor

৳145,000.00

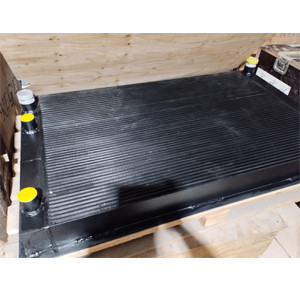

Hydraulic Gear Motor RGV4G04010001 | Brand New |

Premium Quality Best Electric Motor Price in Bangladesh

৳260,000.00