Auto Rice Mill | Brand New Project |

Inhouse product

-

REXROTH Hydraulic Valve R901226876 | New |

৳10,500.00

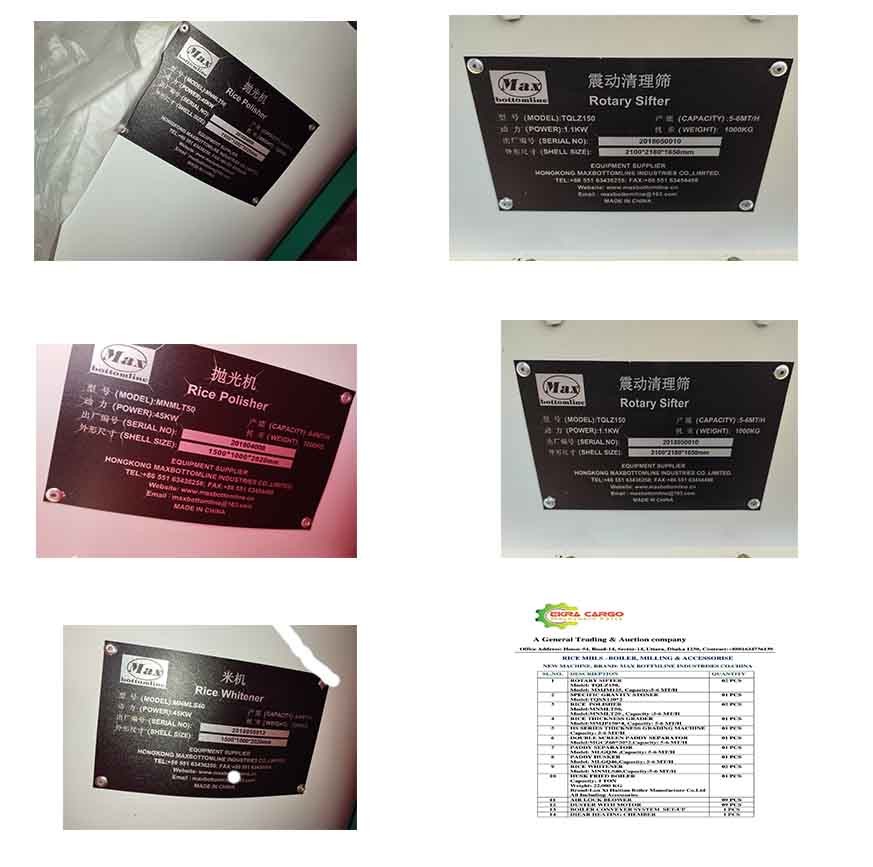

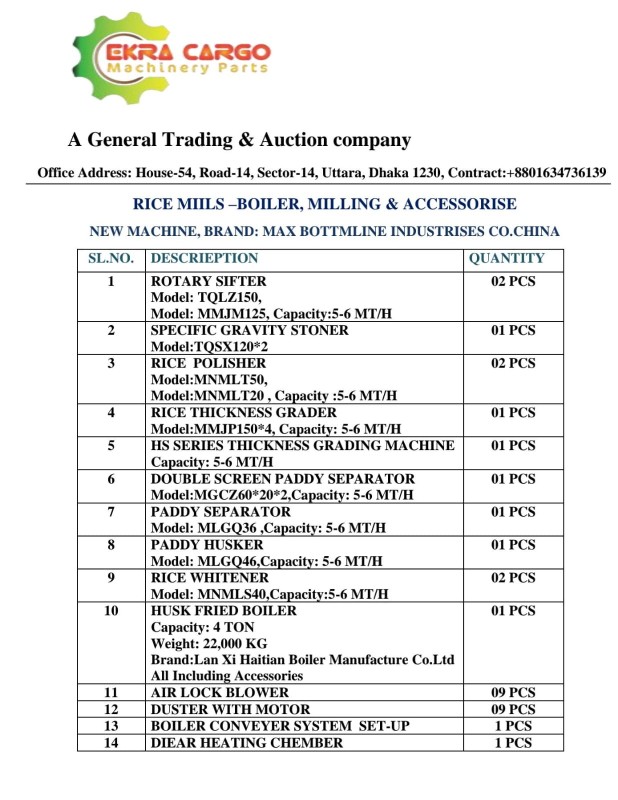

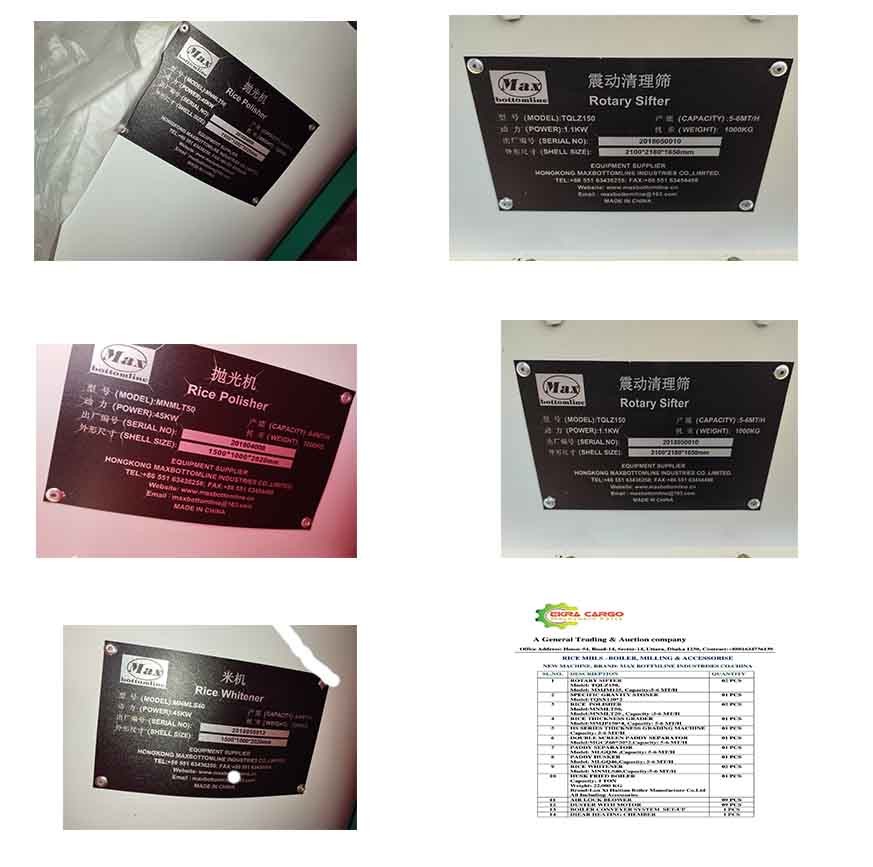

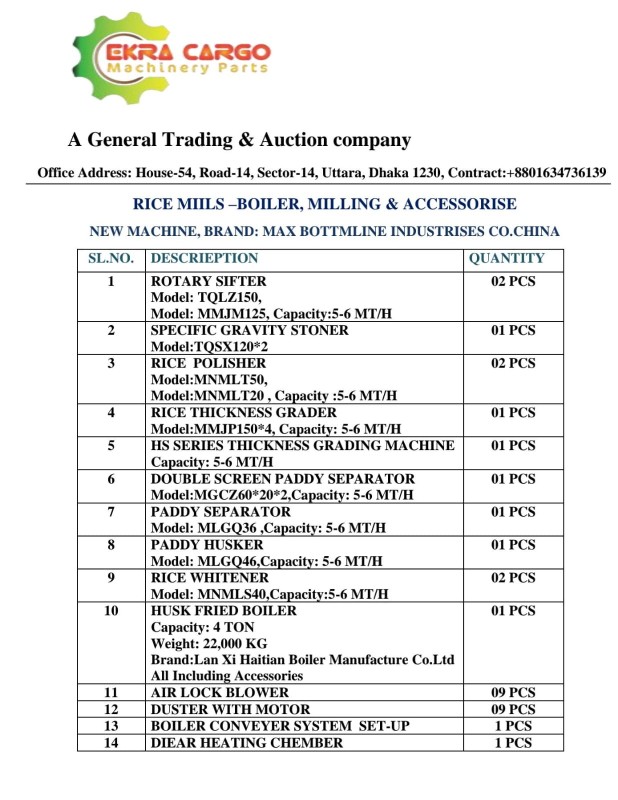

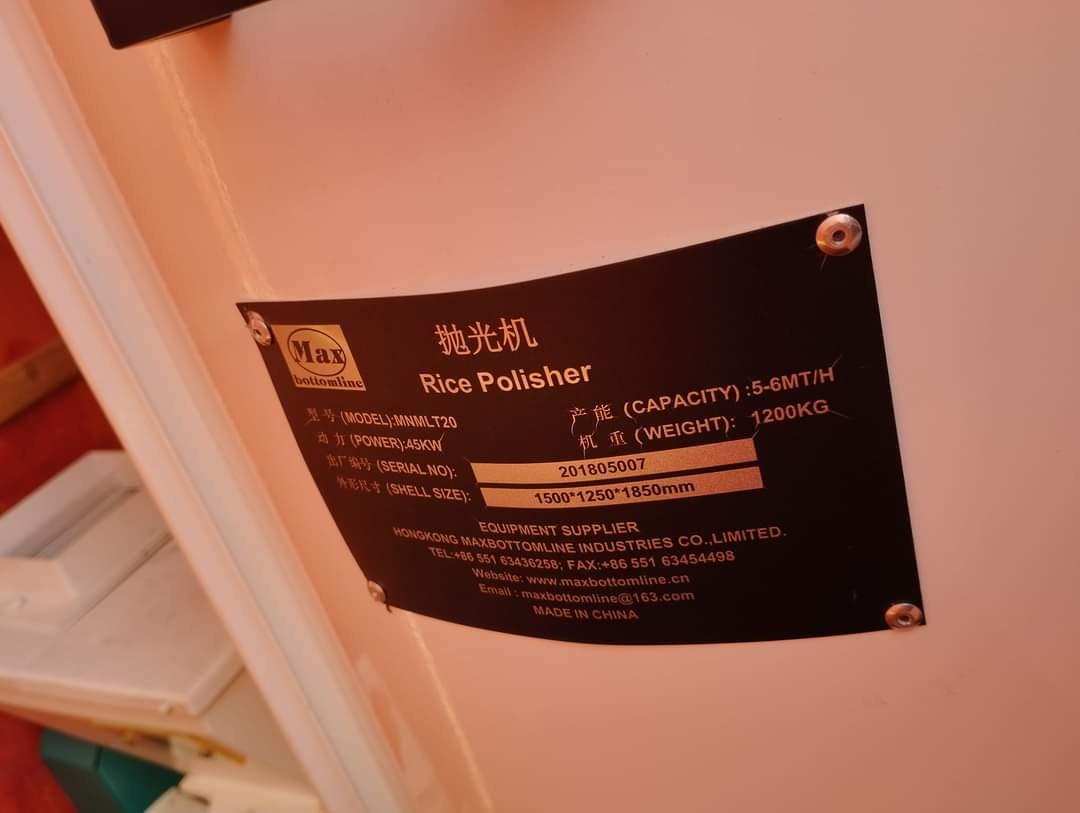

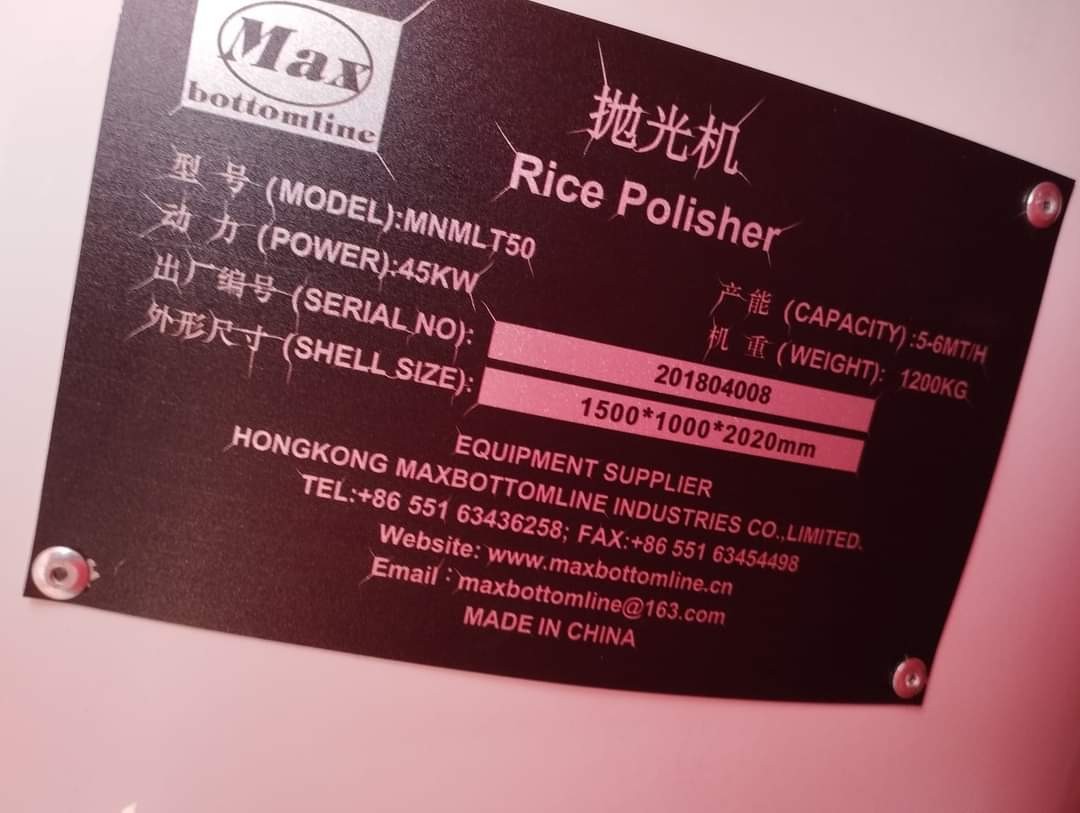

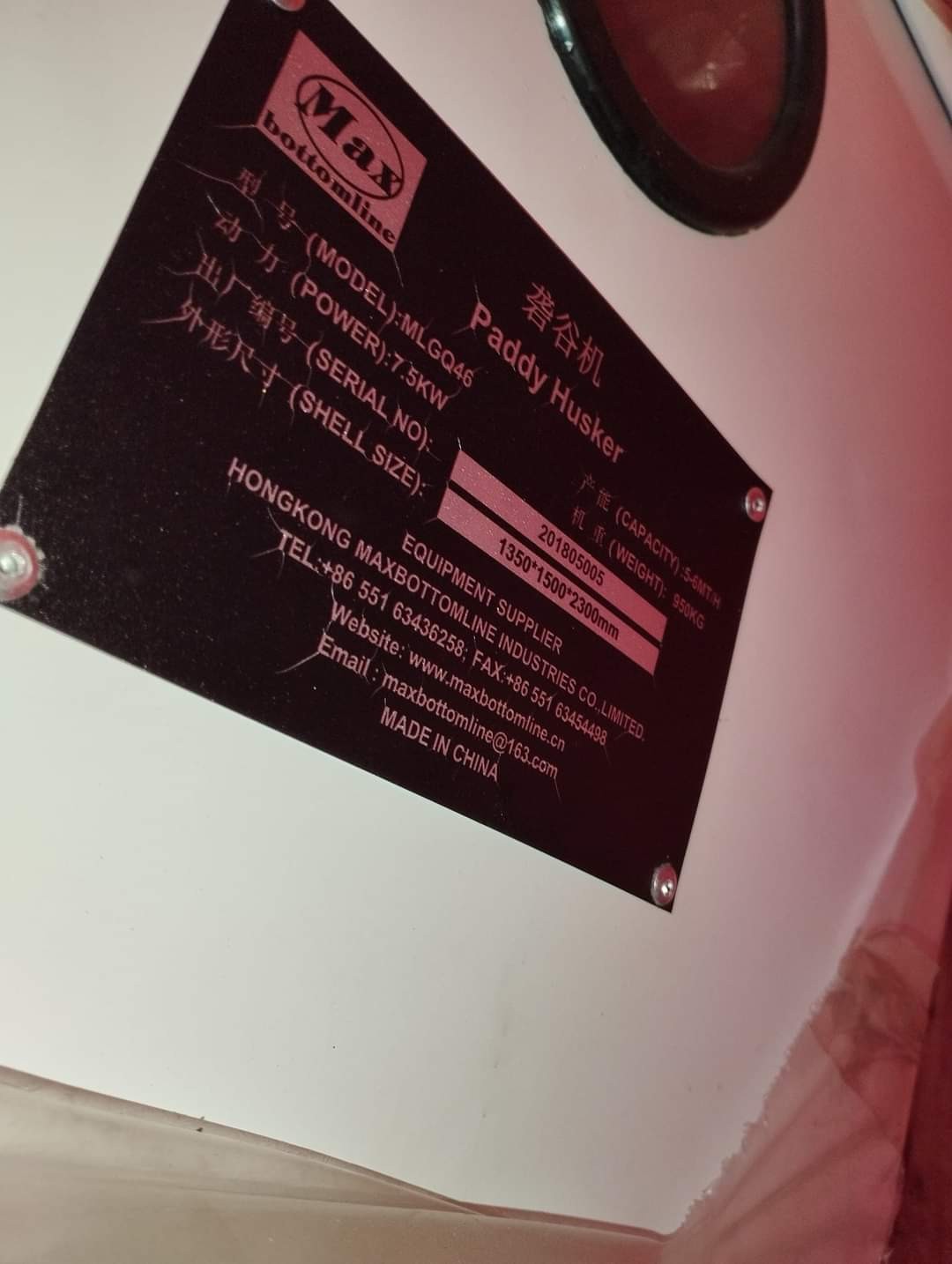

Rice Mills and Polishing Operations

Project on Automatic 5-Ton Rice Mills

The automated 5 tons rice mill project possesses the ability to provide high

quality, uniform, and efficient rice milling. With the new technology and equipment of the

renowned brand Max Bottmline, the project possesses the ability to grind 5 tons

of paddy in an hour. The equipment includes some of the major components

like rotary sifters, gravity stoners, polishers, graders, separators, huskers,

whitening machines, and ancillaries like boilers, blowers, and driers.

From Hand to Automatic: The Transformation of Rice Milling

Milling Section Installation: The milling section is a chain of machines connected in succession for paddy milling and processed rice production. The key elements that compose the installation are: Revolutionizing Rice Milling: From Hand to Automated Operations

Rotary Sifter (2 sets): The sifters efficiently separate foreign matter and dust from the paddy for purity of rice grains.

Gravity Stoner (1 no.): The machine utilizes the force of gravity to

remove stones and other heavy impurities from the paddy and enhance the quality

of the milled rice.

Rice Milling Revolution: From Traditional Methods to Automated Systems

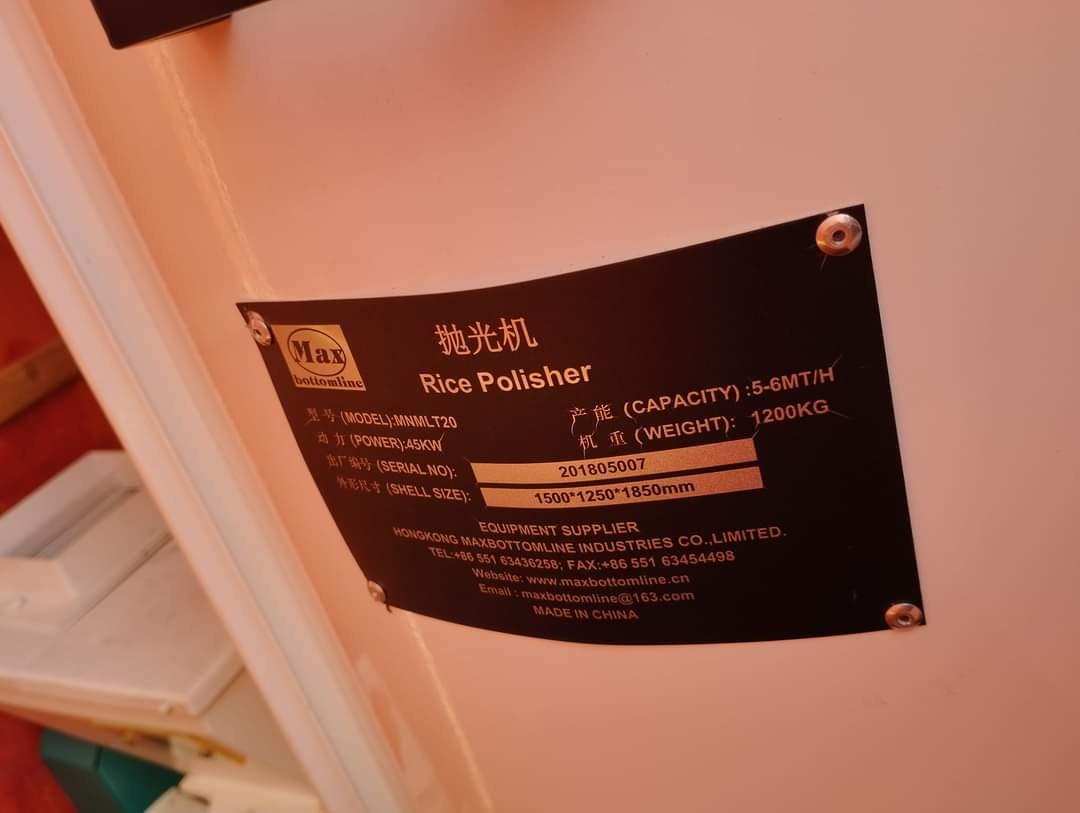

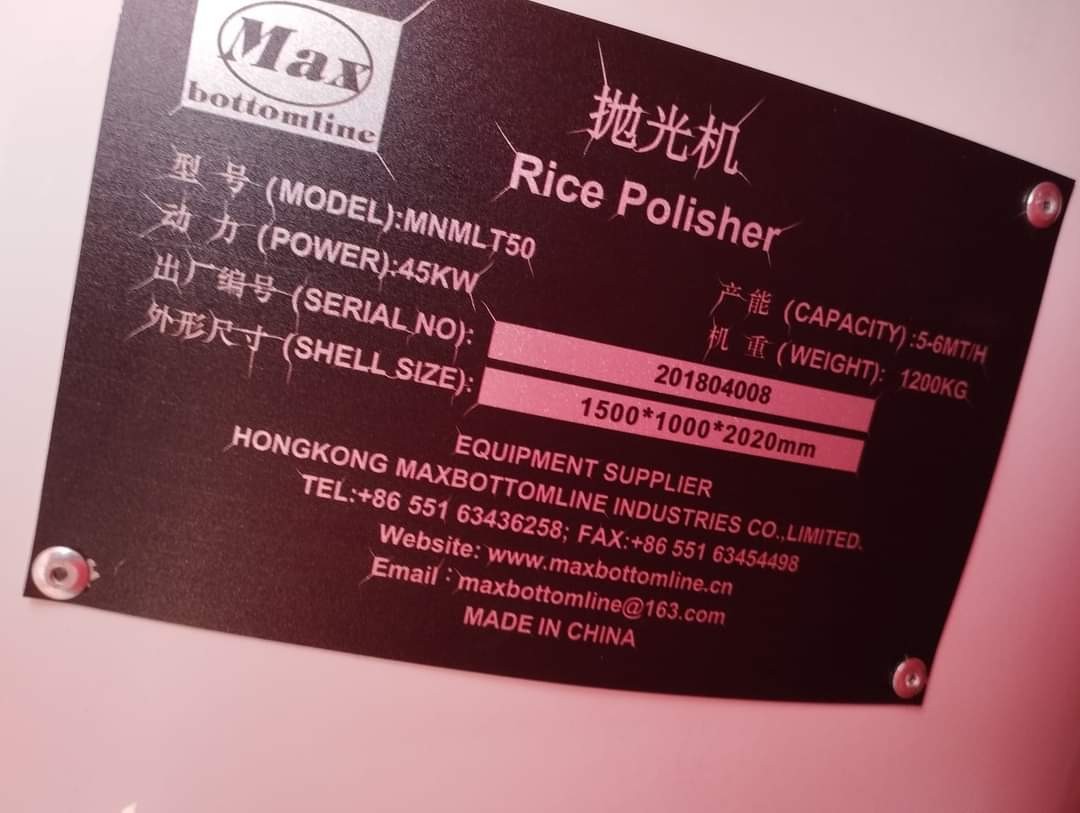

Polisher (2 nos.): Polishers give a shining and smooth finish to the

rice grains, enhancing their market value and beauty. Thickness Grader (2 sets): Thickness graders ensure uniformity in the size and thickness of rice grains, i.e.,

consistent quality in every batch. Paddy Separator (2 sets): Paddy

separators clean the rice grains by removing the husk and other impurities in

order to ready them for processing.

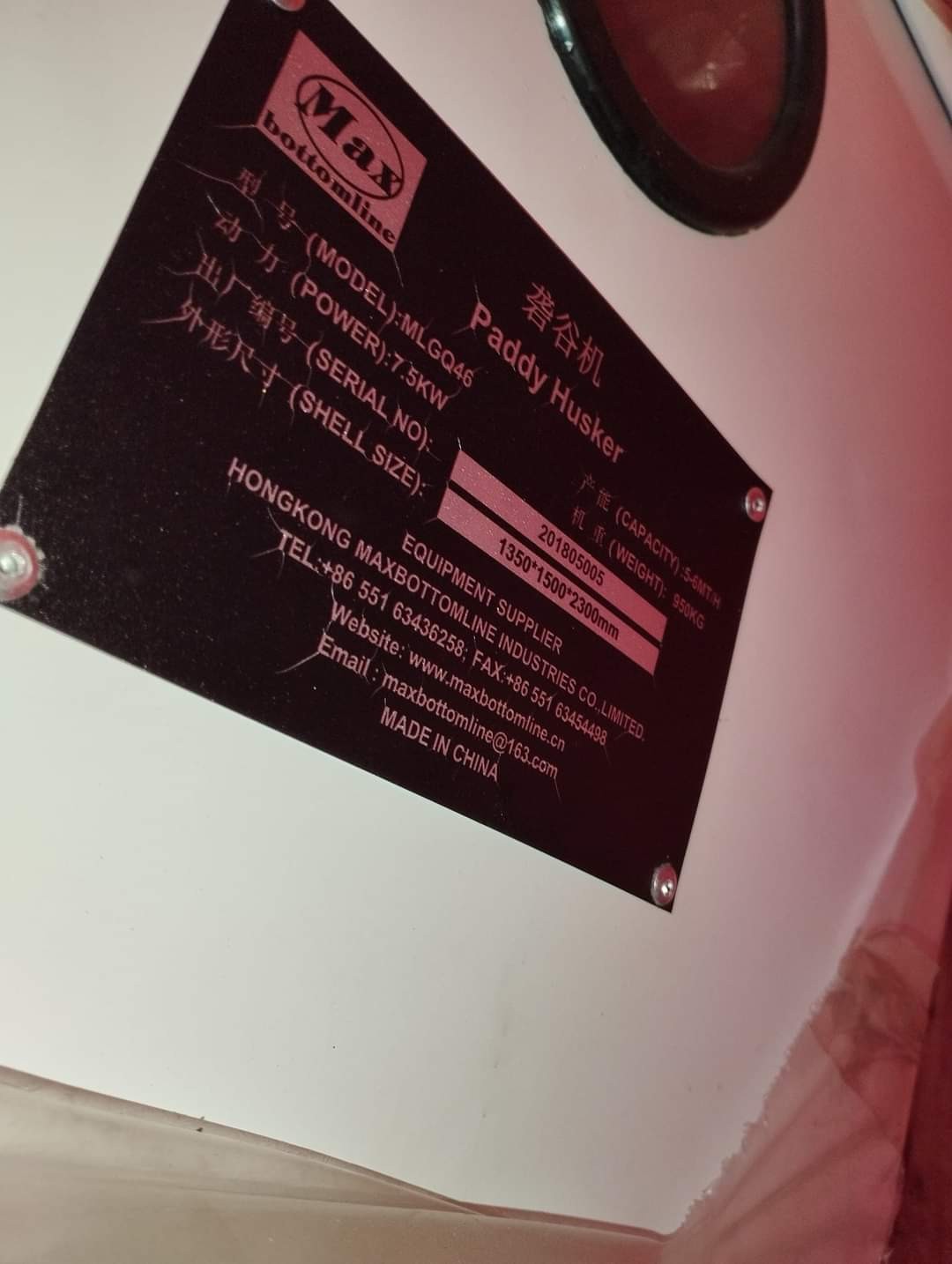

Husker (1 set): Husker strips off the husk layer of the paddy to reveal brown rice for processing.

Optimizing Efficiency: Upgrading the Rice Mills and Polishing Processes

Whitener (2 units): Whitening machine more highly polishes brown rice by

removing bran layers to produce white polished rice.

Husk Fried Boiler (1 unit with Accessories - 4-ton

capacity): Boiler is a very crucial unit in husk frying, providing the heat

used to treat husk and generate steam for most of the mill processes.

Airlock Blower (9 units): Airlock blowers provide smooth passage of rice grains and other materials in the milling process with

consistent flow.

Rice Milling Reinvented: Innovation in Polishing Technology and Automation

Motorized Duster (9 pieces): The dust machines clean the rice grains for

hygiene and quality by removing fine dust and impurities. Boiler Conveyor System: Conveyor system is also provided with the boiler to transport husk and other material efficiently to make the entire milling process easier.

Drier Heating Chamber: Drier heating chamber is

another crucial part that is being utilized to dry the paddy to the optimal

moisture content before milling in order to prevent spoilage and to achieve the

maximum milling output.

5-ton rice mills project with auto technology and

Max Bottmline promises complete solution of efficient and quality rice milling. Modern machinery equipped and properly installed,

the project ensures round-the-clock production with high productivity and less

wastage. With adoption of modern milling techniques and

heavy machinery, the project is likely to meet the rice industry demands

successfully.

Explore More Rice Milling Items